In the fast-paced world of technology, innovation is the key to progress. From communication systems to manufacturing processes, the need for speed, precision, and efficiency is ever-present. One remarkable technology that has been making waves in various industries is the Ultrafast Fiber Laser. This cutting-edge technology is transforming the landscape of applications that require high-intensity, ultrafast laser pulses. In this blog, we will delve into the world of Ultrafast Fiber Lasers, their applications, and their potential to reshape our future.

What are Ultrafast Fiber Lasers?

Ultrafast Fiber Lasers are a type of laser system known for their remarkable capabilities. These lasers generate extremely short laser pulses, typically on the order of femtoseconds or picoseconds. This ultrafast pulse duration is a fundamental feature that sets them apart from traditional laser systems. Fiber lasers use optical fibers as the gain medium, allowing for a compact and robust design.

Applications in Medicine

The medical field has witnessed significant advancements due to Ultrafast Fiber Lasers. Their precise and controlled energy delivery is indispensable for laser surgery, eye surgery, and dermatological treatments. These lasers can selectively target tissues, minimizing damage to surrounding areas. This precision is particularly beneficial in delicate procedures, such as eye surgeries, where the safety of the patient is of utmost importance.

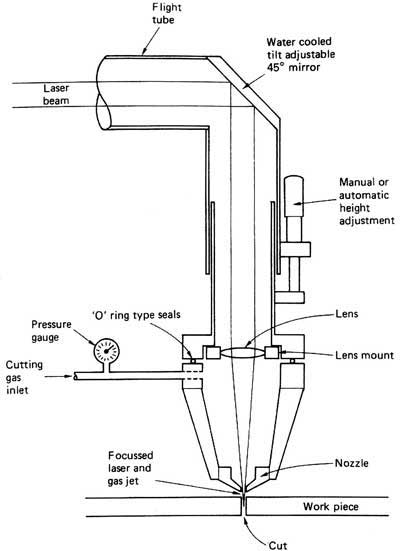

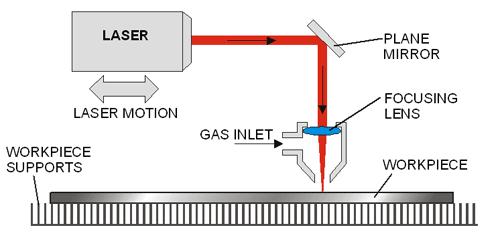

Materials Processing and Manufacturing

Ultrafast Fiber Lasers have also found their niche in materials processing and manufacturing. They are instrumental in the world of micromachining, a process that involves creating intricate and minuscule structures in materials like metals, semiconductors, and ceramics. The ultrafast pulses allow for high-precision cutting and drilling, enabling the production of intricate components for various industries, including aerospace and electronics.

Scientific Research

In the realm of scientific research, Ultrafast Fiber Lasers have become invaluable tools. They are used in a wide range of applications, from ultrafast spectroscopy to studying chemical reactions at the molecular level. Researchers can observe and analyze processes that occur in a fraction of a second, shedding light on previously uncharted territories of science.

Telecommunications

Ultrafast Fiber Lasers play a crucial role in the telecommunications industry, facilitating the transmission of vast amounts of data at incredible speeds. Their ability to generate ultra-short pulses enables the efficient transmission of information through optical fibers, making high-speed internet and telecommunications networks a reality.

Environmental Sensing

Environmental monitoring and sensing benefit from the precision and sensitivity of Ultrafast Fiber Lasers. They are used in LIDAR (Light Detection and Ranging) systems, which provide highly accurate distance and speed measurements. These systems are used in applications ranging from autonomous vehicles to atmospheric research.

The Future of Ultrafast Fiber Lasers

As technology continues to advance, the applications of Ultrafast Fiber Lasers will only expand. Their compact design and exceptional performance make them an attractive choice for a wide range of industries. Whether it’s in medical procedures, materials processing, scientific research, telecommunications, or environmental sensing, these lasers have the potential to revolutionize the way we approach various tasks.

In conclusion, Ultrafast Fiber Lasers are a remarkable innovation that is already leaving a significant mark on several industries. Their precision and speed are changing the way we perform medical procedures, manufacture products, conduct scientific research, and communicate. As the technology continues to evolve, it’s safe to say that we’ve only scratched the surface of what Ultrafast Fiber Lasers can achieve. The future looks bright, and it’s powered by light – ultrafast light, to be precise.