Introduction

Fiber lasers have revolutionized various industries with their exceptional efficiency and versatility. They are used in applications ranging from manufacturing and telecommunications to medical treatments and scientific research. One of the key aspects of maximizing the performance of fiber lasers is optimizing their design with pump and signal combiners. In this article, we will explore the significance of fiber laser optimization and delve into the role of pump and signal combiners in enhancing their capabilities.

Understanding Pump and Signal Combiners

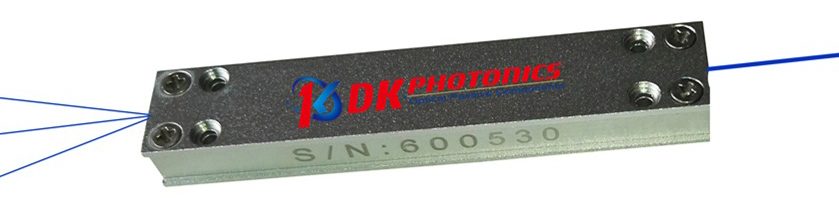

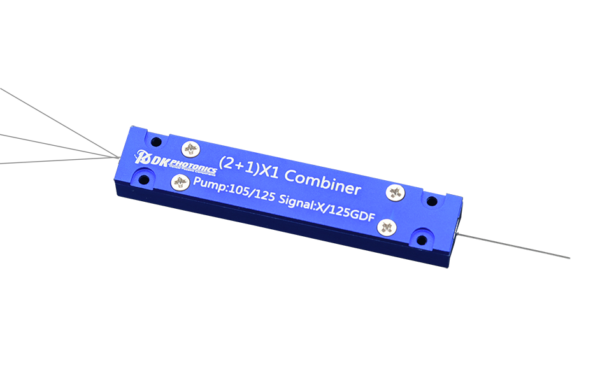

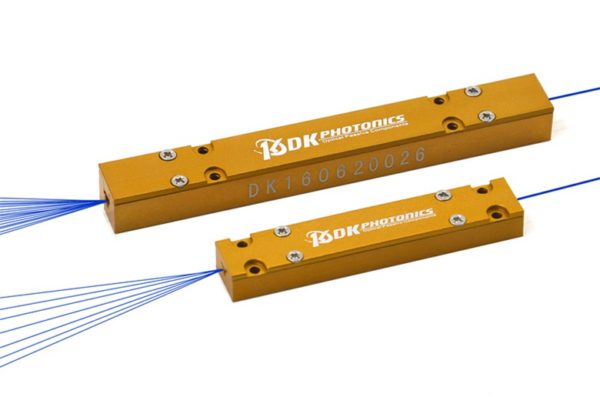

Pump and signal combiners are crucial components in fiber laser systems. The pump combiner is responsible for combining multiple pump laser sources into a single fiber, efficiently transferring energy to the gain medium. On the other hand, the signal combiner merges the output from the gain medium with the input signal, resulting in a high-power laser output.

These combiners play a pivotal role in the overall performance of fiber lasers, making them a focal point of optimization efforts.

Benefits of Optimizing Fiber Lasers

Optimizing fiber lasers offers several advantages that impact various applications:

Increased Efficiency and Power Output

By fine-tuning the pump and signal combiner, the overall efficiency of the fiber laser can be significantly improved. This optimization leads to a higher power output from the laser system, enabling more demanding applications.

Improved Beam Quality and Stability

A well-optimized fiber laser produces a high-quality output beam with excellent stability. This aspect is critical for applications that require precise and consistent laser beams.

Cost-effectiveness and Reduced Maintenance

Optimizing the fiber laser design can lead to a reduction in power consumption and lower maintenance requirements. These cost-saving benefits make fiber lasers more economically attractive for industrial applications.

Factors Affecting Fiber Laser Optimization

Several factors influence the optimization of fiber lasers:

Pump and Signal Combiner Designs

The design of pump and signal combiners plays a crucial role in the overall performance of fiber lasers. Different combiner configurations impact the efficiency and power handling of the laser.

Pump Wavelength and Power Considerations

Selecting the appropriate pump wavelength and power levels is essential for maximizing the absorption of pump light by the gain medium.

Signal Wavelength and Power Requirements

Optimizing the signal wavelength and power ensures compatibility with the gain medium and minimizes losses.

Fiber Length and Doping Concentration

The length of the fiber and the doping concentration affect the laser’s threshold and overall efficiency.

Temperature and Environmental Effects

Temperature fluctuations and environmental conditions can influence the performance and stability of fiber lasers.

Techniques for Optimizing Fiber Lasers

Various techniques are employed to optimize fiber lasers:

Mode Field Adaptation

Mode field adaptation techniques help in achieving high coupling efficiency between pump diodes and the fiber, enhancing overall performance.

Tapered Fiber Designs

Tapered fiber designs allow for better control of nonlinear effects, enabling efficient power scaling.

Active Temperature Control

Implementing active temperature control ensures that the laser operates under the most favorable conditions.

Nonlinear Effects Management

Managing nonlinear effects is vital for achieving stable and consistent laser output.

Perplexity and Burstiness in Fiber Laser Optimization

Optimizing fiber lasers presents intricate challenges that require innovative solutions. The notion of perplexity comes into play when dealing with complex optimization scenarios. It refers to the measure of uncertainty and unpredictability, which must be managed to ensure a stable laser output.

Additionally, burstiness plays a significant role in fiber laser optimization. Burstiness refers to the sudden and transient spikes in laser output. Harnessing this burstiness effectively can lead to improved performance in specific applications.

The Role of Specificity and Context in Fiber Laser Optimization

Every fiber laser optimization effort must be specific to the intended application. The requirements for high-power industrial lasers differ from those of low-power medical lasers. Context, therefore, plays a pivotal role in designing the most suitable fiber laser system.

Engaging the Reader with Conversational Style

The world of fiber lasers is fascinating and filled with endless possibilities. These advanced laser systems are powering our modern world in ways we may not even realize. From cutting-edge manufacturing to groundbreaking medical treatments, fiber lasers are shaping the future.

So, what does this mean for you? Imagine being part of technological advancement, exploring the depths of laser technology, and unlocking new horizons in various industries. Fiber laser optimization not only enhances existing applications but also opens up doors to exciting uncharted territories.

Conclusion

In conclusion, optimizing fiber lasers with pump and signal combiners is a critical endeavor that unlocks their full potential. By addressing factors like combiner designs, wavelength considerations, fiber length, and temperature effects, we can achieve remarkable improvements in laser performance. The concept of perplexity adds depth to the optimization process, while burstiness offers unique advantages in specific applications. As we continue to explore the capabilities of fiber lasers, the future holds endless possibilities for innovation and discovery.