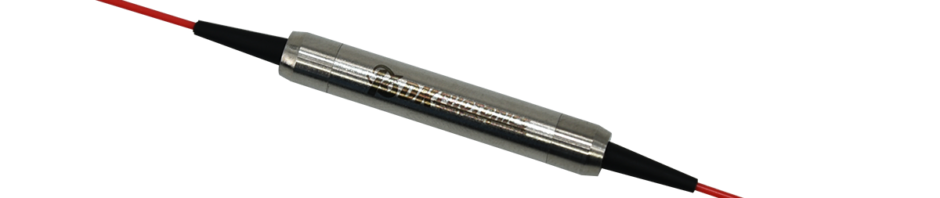

Fiber Bragg Gratings arrays are designed for strain and temperature measurement.

Fiber Bragg Gratings written within optical fibers offer great resolution and robustness, making them perfect for temperature or mechanical strain monitoring applications. Real-time safety and function monitoring is becoming increasingly important in areas ranging from transportation, aviation, and aerospace to civil engineering and oil and gas. This technology can be used to monitor strain in a concrete structure, the movement of an aircraft wing, the detection of pipeline leaks, and so on.

Applications of FBG Array

Fiber Bragg Gratings (FBGs) are outstanding sensor elements that can measure temperature, strain, pressure, tilt, displacement, acceleration, load, and the presence of different industrial, biomedical, and chemical compounds in both static and dynamic modes of operation. In addition, the FBG is a superb signal-shaping and filtering element for a wide range of applications. FBG array is used in the following industries:

- Geotechnical and civil engineering

- Electricity production, conversion, and storage

- Transportation for commercial purposes

- Vessels, vehicles, and equipment with high performance

- Security and perimeter surveillance

- Medical and biotechnology

- Industrial

- Industrial

- Research and development

The Advantages of FBG Array

A Bragg grating, as a fiber optic sensor, has all of the benefits typically associated with these devices, such as low loss relative to fiber length, immunity to electromagnetic and radio frequency interference, small size and weight, intrinsically safe operation in hazardous material environments, high sensitivity, and long-term reliability. Furthermore, Fiber Bragg grating technology demonstrates an inherent serial multiplexing capability as well as the potential to deliver absolute measurements without the use of referencing.

Operation

The FBG will serve as a wavelength-selective mirror as a resonant structure; it is a narrow-band filter. This means that if light from a broadband source is introduced into the optical fiber, the grating will back-reflect only light with an extremely limited spectral width centered on the Bragg wavelength. The leftover light will travel without interruption via the optical fiber to the next Bragg grating.

Acting as a strain sensor

An FBG has special properties that allow it to function as a sensor. The FBG, for example, will measure strain when the fiber is stretched or compressed. This occurs because optical fiber deformation changes the period of the microstructure and the Bragg wavelength.

Serving as a temperature sensor

A Fibre Bragg grating is also temperature sensitive. The shift in the silica refraction index caused by the thermo-optic effect is the main contributor to the Bragg wavelength change in this scenario. The thermal expansion also affects the period of the microstructure. However, because of silica’s low coefficient of thermal expansion, this effect is minor.

Multiplexing

One of the primary benefits of this technology is its inherent multiplexing capabilities. Hundreds of fiber Bragg gratings can be inscribed on a single optical fiber, which can be as near as a few millimeters apart or as far apart as a few kilometers. Each of these microstructures can be made responsive to parameters other than temperature or strain with suitable packaging.

It is critical to note that all of the sensors can be addressed by a single light source. Furthermore, as long as enough spectral band of the light spectrum is reserved for each sensor, the addition of more and more sensors on the same fiber results in relatively small loss and no crosstalk.

The FBG Array is a collection of Bragg gratings inscribed on a single optical cable. It can handle long-term monitoring as well as multi-point monitoring. It can improve system stability and reliability while also simplifying the system. Contact DK Photonics to personalize the FBG array according to you.