Polarization beam combiners/splitters are fascinating devices used in optics and telecommunications. In this blog, we’ll delve into the world of High Power Polarization Beam Combiner/Splitter, shedding light on what they are, how they work, and their applications without getting too technical.

What is a High Power Polarization Beam Combiner/Splitter?

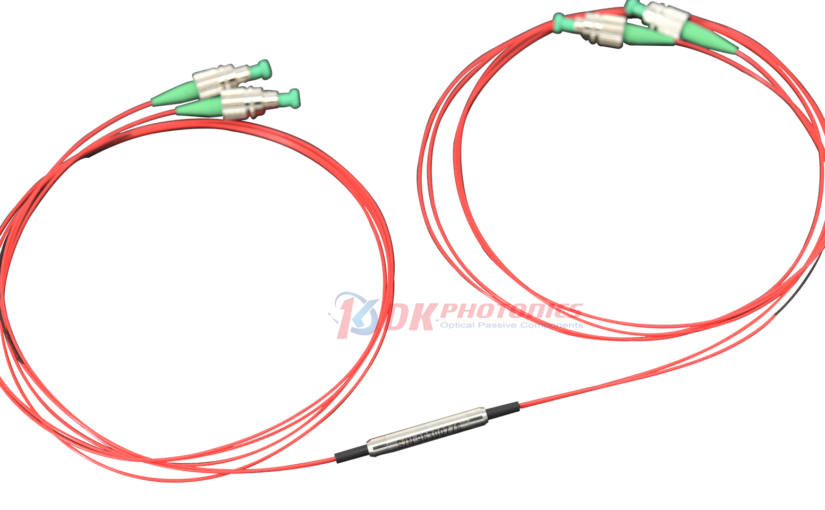

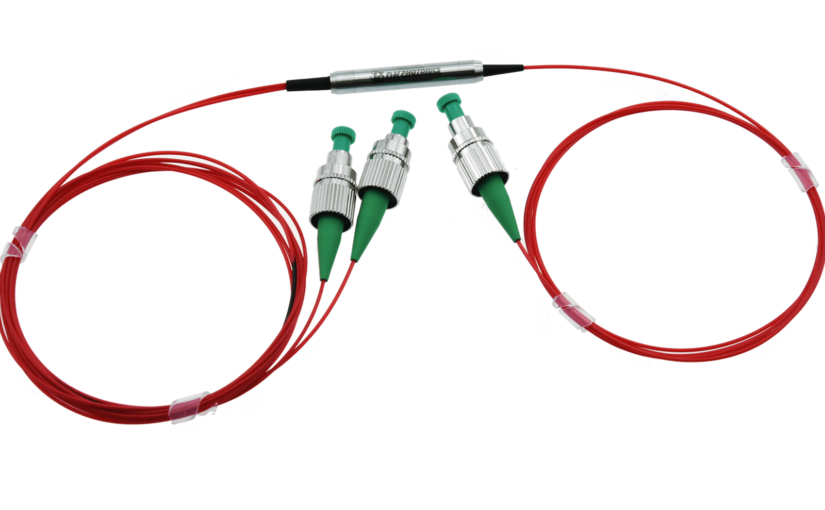

- Introduction: A High Power Polarization Beam Combiner/Splitter is a specialized optical component used to manipulate light waves based on their polarization.

- Functionality: It combines or splits light beams from input fibers, effectively managing the polarization of light.

How Does it Work?

- Combining Light: When used as a combiner, it merges light beams from two polarization-maintaining (PM) input fibers into a single output fiber.

- Splitting Light: As a splitter, it divides light from an input fiber into two output fibers based on their polarization.

Applications

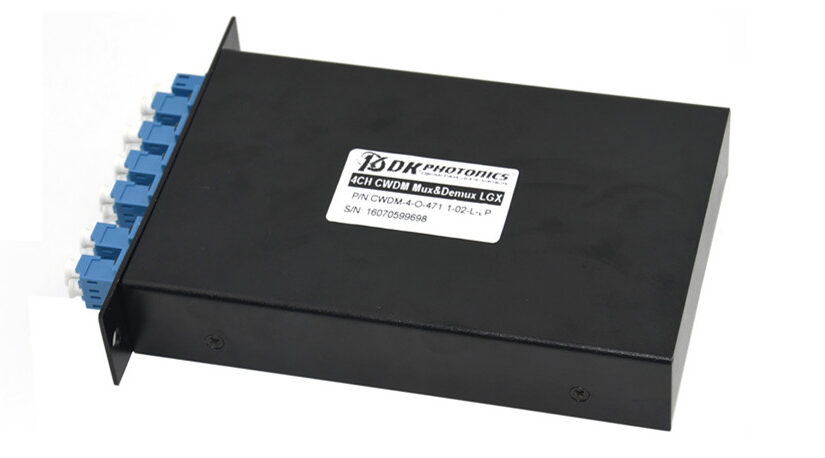

- Telecommunications: In the telecom industry, these devices are crucial for managing and manipulating light signals efficiently.

- Optics Research: High Power Polarization Beam Combiner/Splitters are also indispensable in optical research for various experiments and studies.

Advantages

- Efficiency: They offer high power handling capabilities, making them suitable for demanding applications where power levels are crucial.

- Versatility: These devices are versatile and can be tailored to specific requirements, providing flexibility in different setups.

Conclusion

High Power Polarization Beam Combiner/Splitters are vital components in optics and telecommunications, facilitating the manipulation and management of light waves with precision and efficiency. Whether it’s combining or splitting light beams, these devices play a crucial role in various applications, from telecommunications infrastructure to advanced optical research. With their high power handling capabilities and versatility, they continue to be indispensable tools for researchers and engineers pushing the boundaries of light-based technologies.