Have you ever wondered how certain optical devices can magically filter light to reduce glare, enhance image quality, or even make 3D movies possible? In the fascinating world of optics, one of the key players in achieving these effects is the in-line polarizer. In this article, we’ll take an in-depth journey into the realm of polarizers, exploring their inner workings, applications, and the science behind their mesmerizing feats.

1. Introduction to Polarizers

Polarizers are optical devices designed to control and manipulate the orientation of light waves. By allowing light waves to pass through in a specific direction, polarizers play a pivotal role in a wide range of industries and technologies.

2. Understanding Polarized Light

Before delving into in-line polarizer, it’s essential to grasp the concept of polarized light. Light, which usually travels in all directions, becomes polarized when its waves oscillate predominantly in one plane.

3. Types of Polarization

There are two primary types of polarization: linear and circular. Linear polarization occurs when light waves vibrate in a single plane, while circular polarization involves the rotation of light waves as they propagate.

4. What are In-line Polarizers?

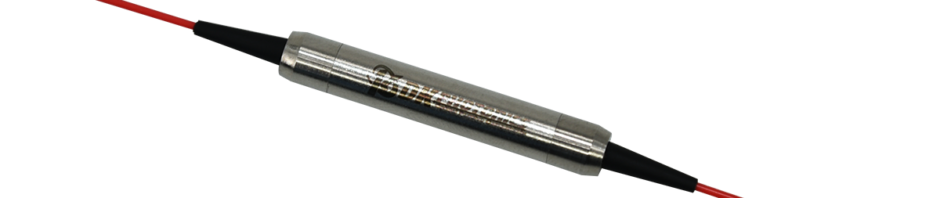

In-line polarizers are specialized optical components that transmit light waves with a specific polarization while blocking or attenuating light waves of other polarizations. They are often used to enhance visual clarity and reduce glare.

5. How In-line Polarizers Work

In-line polarizers employ various techniques, such as dichroism or birefringence, to selectively filter light waves based on their orientation. These devices consist of aligned molecules or microstructures that interact with incoming light to achieve the desired polarization effects.

6. Applications in Everyday Life

In-line polarizers have found their way into numerous aspects of our daily lives. Sunglasses, for instance, use polarizers to reduce glare from reflective surfaces like water or roads, making outdoor activities more comfortable.

7. In-line Polarizers in Photography

Photographers often use polarizers to enhance the quality of their images. By reducing reflections and boosting color saturation, these polarizers enable the capture of stunning landscapes and vivid scenes.

8. The Role of Polarizers in 3D Technology

Polarizers play a crucial role in 3D technology, particularly in stereoscopic cinema. They enable the separation of images intended for the left and right eyes, creating the illusion of depth in 3D movies.

9. Polarizers in LCD Screens

LCD screens utilize liquid crystal in-line polarizers to control the passage of light and create the images we see. The liquid crystals can be manipulated to adjust the polarization state of the transmitted light.

10. Polarization in Physics and Astronomy

Polarization phenomena extend to the field of physics and astronomy. By studying the polarization of light from celestial objects, scientists can gain insights into the properties of stars, galaxies, and interstellar matter.

11. Manufacturing and Technology Behind Polarizers

The production of high-quality in-line polarizers involves intricate manufacturing processes, including precise alignment of molecules or microstructures. Advanced technologies ensure consistent performance and reliability.

12. Challenges in Polarizer Design

Designing effective polarizers comes with challenges. Achieving broad-spectrum polarization, reducing energy loss, and adapting polarizers for specific environments are some of the ongoing design considerations.

13. Advancements and Future Possibilities

As technology advances, new applications for in-line polarizers continue to emerge. From augmented reality to medical imaging, these devices hold the potential to revolutionize various industries.

14. Making the Right Choice: Selecting Polarizers

Choosing the appropriate in-line polarizer depends on factors such as intended application, wavelength range, and desired polarization efficiency. Careful consideration ensures optimal results.

Conclusion

In-line polarizers stand as remarkable tools that manipulate light to serve a myriad of purposes. From enhancing visual experiences to advancing scientific research, these devices unlock a world of possibilities through the precise control of polarized light.