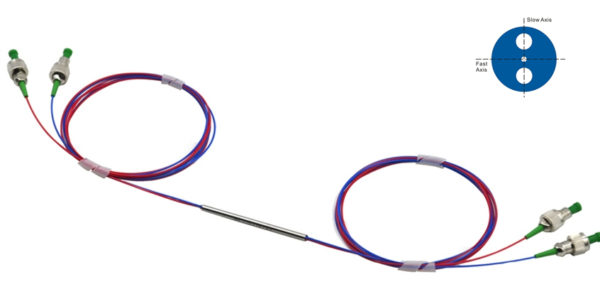

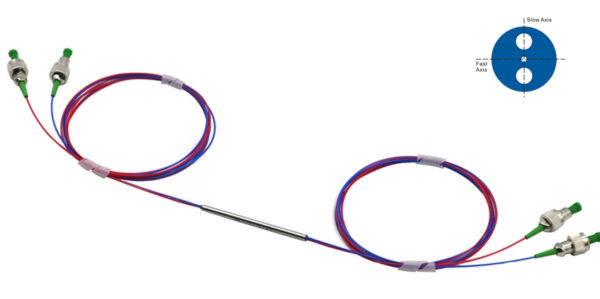

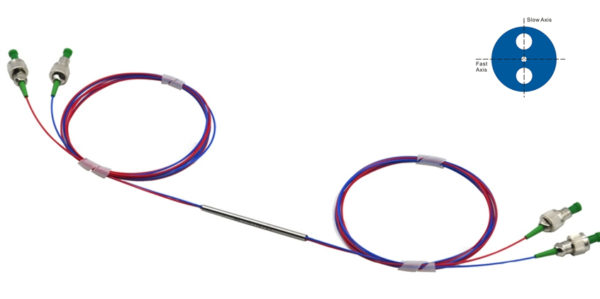

To effectively couple light into polarization-maintaining fibers and maintain polarization states, polarization-maintaining fused couplers are essential components.

To fabricate polarization maintaining fused couplers with high precision and reliability—factors that have a direct impact on the functionality and general standard of optical systems—it is necessary to use sophisticated procedures. We will examine the fabrication methods used for polarization maintaining fused couplers in this blog article, emphasizing their importance in achieving high precision and reliability.

Low-Loss Fiber Fusion Splicing:

The fusion splicing of polarization-maintaining fibers is a fundamental step in the construction of polarization-maintaining fused couplers. To create seamless connections between the fibers, low-loss fusion splicing methods are used. To ensure minimum insertion loss and polarization-dependent loss (PDL), sophisticated fusion splicing machines with precise alignment capabilities are used. For the best fusion splicing quality, these machines provide accurate fiber location, control of fusion settings, and real-time feedback.

Fiber Tapering:

A sophisticated method for producing progressive changes in the fiber diameter is fiber tapering. To maximize mode field matching between fibers and minimize coupling efficiency, this approach is used in polarization-maintaining fused coupler construction. The mode fields of the fibers can be perfectly matched by carefully managing the tapering process, which improves coupling efficiency and lowers insertion loss.

Polarization-Maintaining Fiber Alignment:

For polarization-maintaining fused couplers to operate at their best, precise alignment of the polarization-maintaining fibers is essential. To guarantee accurate alignment of the fibers, cutting-edge alignment methods such as automated alignment systems, computer vision algorithms, and feedback control mechanisms are used. By using these methods, the fiber cores may be aligned with sub-micron accuracy, coupling losses are reduced, and polarization preservation is maximized.

Controlled Fusing Process:

To produce the best results, the fusing process used in polarization maintaining fused coupler production necessitates exact control over variables including temperature, duration, and pressure. Modern fabrication methods use fusing systems that are computer-controlled to provide fine control over these characteristics. By ensuring consistent and repeatable fusing outcomes through the use of feedback mechanisms and temperature profiling, polarization maintaining fused coupler reliability is increased while performance variances are minimized.

Stress Management and Birefringence Compensation:

The performance of polarization-maintaining fused couplers can be harmed by stress-induced birefringence, which can occur in polarization-maintaining fibers. To reduce the effects of stress-induced birefringence, advanced fabrication procedures use stress management and birefringence compensating techniques. To produce the appropriate birefringence qualities, these procedures involve fine-tuning tension during the production process, stress relaxation mechanisms, and fiber parameter optimization.

Post-Fabrication Testing and Characterization:

Rigid testing and characterization techniques are used to guarantee the high precision and dependability of polarization-maintaining fused couplers. Key characteristics such as insertion loss, PDL, extinction ratio, and coupling efficiency are evaluated using sophisticated measuring methods such as polarimetric analysis, interferometry, and optical spectrum analysis. These tests confirm that PMFCs perform as expected and conform to the required standards.

Conclusion:

To fabricate polarization maintaining fused coupler with high accuracy and reliability, manufacturing procedures are essential. By ensuring the preservation of polarization states and boosting the overall performance and dependability of the systems, these solutions support the optimal performance of polarization-maintaining fused couplers in optical communication systems.

sors and optical gyro requires high polarization extinction ratio.

sors and optical gyro requires high polarization extinction ratio.