Communication networks are vulnerable to data congestion. This limits the end users from accessing certain links including mobile radio towers. The problem has led to management of dedicated links by a large number of wireless carriers through the optical fiber network connection.

Depending on the requirement standards the service provider is expected to comply, some even go to the extent of claiming additional dedicated strands which give access and core meshes to the mobile tower sites. This trend depletes the number of available fiber strands denying new service providers access to mobile towers.

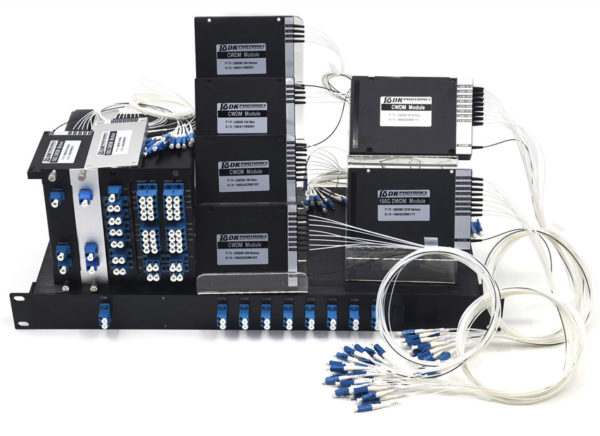

Thanks to the art of technology which has introduced data bottleneck solution to businesses. The compact CWDM multiplexer allows fiber capacity enhancement without the need to increase the number of fiber strands. This ensures easy communication and connectivity to mobile towers by giving quick access without bugs.

Features

- High channel isolation

- Mini size

- High insertion loss

- Epoxy-free optical path

- Large bandwidth

Applications

- Mobile phone applications

- WDM network

- Access network

- Tele-communication

- Fiber optic amplifier

How it works

Compact CWDM multiplexer works by either extracting or inaugurating several signals which are broadcasted through different fiber wavelengths to efficient create more different channels. A MUX conglomerates individual light channels to the fiber at the sending end of the data link.

On arrival, a demultiplexer (DEMUX) applies a similar optical conformation in a reverse direction, propagating via the device. The DEMUX optical filter singles out the incoming wavelengths and pairs each channel separately with fiber. This increases the number of channels transmitted through the fiber.

As the demand for more subscribers continues to grow, the CWDM scales the supply of additional bandwidth by handling bottlenecks without substantial equipment modification. According to the IEEE standards. CWDM is compact and has the capability of withstanding outside plant (OSP) environmental conditions. This allows deployment of uncooled and unheated equipment and cabinets.

Advantages

Saves money

CWDM helps access network operators lower their costs by providing quality connections to their users without the need of investing on more fiber links.

High quality

Compact CWDM is designed using modern technology and complies with IEEE standards making service providers meet the global communication standards. Besides, the device has the capability of withstanding outside the plant environmental conditions giving providers favorable installation conditions.

Reduces data bugs

Networks are prone to bottlenecks. However, the device scales additional bandwidth without the need of substantial modification of the device. This ensures quick access to links despite the increase in the number of subscribers. This has enabled users to enjoy high-speed internet, telephony services, and on-demand videos without limited access.

Before making use of this new technology, access network operators must satisfy the following requirements.

- Bandwidth of up to 10Gps for each first-time backhaul link

- Facility to storing stable legacy fiber connections of between 1550nm or 1310nm

- Typical spans of up to 80km

- Uncomplicated operations which are reliable

- Wireless carrier segregation bandwidth

- Packaged and long-lasting environmental constraints for installation