High power isolator plays an important role in industrial control systems. Also known as a signal isolator, it basically isolates, input, output, and the working power from each other. Therefore, it is mainly installed in those equipment and systems that require electrical isolation. In other words, an isolator is a mechanical switching device that allows the isolation of the input and output of the device in the open position. To meet the varied requirements of different applications, it is available in different specifications such as 1064nm High Power Isolator, 1080nm High Power Isolator, 1030nm high power isolator, 980nm high power isolator, and so on.

In this post, you will learn about the need of isolators and their types.

Reason to Use Isolators

Isolators are mechanical switches that are used to separate the part of electrical power. They can open a circuit under no load. The main purpose of using isolators in systems is to isolate one portion of the circuit from the other which is not intended to be opened while current is flowing. They are generally used on both ends of the break so that repair or replacement can be done without any danger.

Reasons for Interference in the System

There are several reasons which make the systems unstable such as:

- Weak signal transmission in automation instrumentation, control systems, and actuators

- Use of Small (millivolt, microampere) to large signals (thousands of volts, hundreds of amperes)

- Signal systems with low frequency to high-frequency pulse

In addition to this, anti-electromagnetic interference is also an important factor. The presence of a potential difference between instruments and equipment between signal interference points leads to the formation of ground loops caused during signal transmission in the distortion process.

So, the problem of ground loop must be solved in the process of system signal processing to ensure the stable and reliable operation of the system.

Possible Solutions to Ground Loop Problem

According to theory and practical analysis, there are three solutions to the ground loop problem including all site equipment grounding, creation of the same electrical potential of two junctions and signal isolation method.

Among all of them, signal isolation is the most suitable and practical solution as it can break the loop without interfering with the normal transmission of the process signal. Thus, it can be used to completely solve the ground loop problem.

Types of Isolators

There are different types of isolators based on the requirement of the system.

- Single-break Isolator – in which arm contact is separated into two elements

- Double-break Isolator – consists of three loads of post insulators

- Pantograph Isolator – permits current switchgear installation and requires the least space

However, according to the power system location, they can be categorized into three types, for instance:

- Bus Side isolator – which is connected by the major bus

- Line Side Isolator – which stays connected by a feeder in line side

- Transfer Bus Side Isolator – which stays connected by the major bus of a transformer

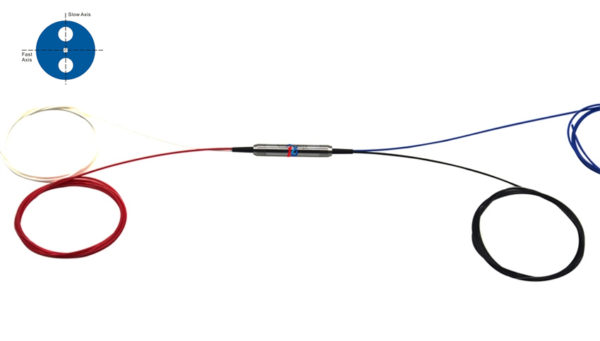

If you are in need of any type of isolator including 1064nm high power isolator, 1080nm high power isolator, or isolators in other customized specifications, ensure that you contact a high power isolator manufacturer online that has a strong presence and reputation in the market.