Instead of diving straight into complexities of polarization maintaining tap coupler, let’s first discuss what an optical coupler simply is. An optical coupler is a device which can join one or more optic fiber ends for transmitting light waves in multiple paths. It is capable of combining two or more inputs into a single output as well as dividing a single input into two or more outputs. If you compare it with a splice or a connector, you will find that with an optical coupler, the signals can be more attenuated as the input signal can be distributed among the output ports.

In general, fiber optic couplers can be divided into two categories: active and passive.

For active coupler, an external energy source is required. On the other hand, there is no requirement of power to operate passive couplers.

In the market, you will find different types of fiber optical couplers such as X coupler, combiner, splitter, stars and trees. This categorization is carried out on the basis of the number of input and output ports.

As the name implies, a combiner does the work of combining two signals and providing a single output. Similarly, a splitter does the functioning of dividing a single optical signal to facilitate two output signals. It can further be divided into Y couplers and T couplers. If we talk about star couplers, they distribute power from inputs to outputs. While some tree couplers take multiple input signals and provide one output signal, others take a single input and provide multiple output signals.

Fiber optic couplers are manufactured using a variety of technologies such as planar waveguide, fused-fiber and micro optics.

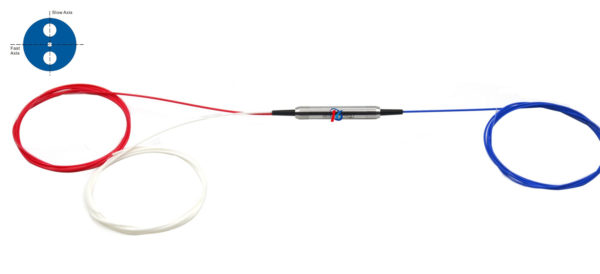

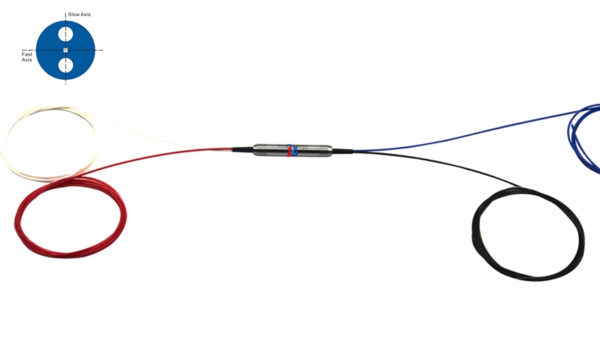

Now, let’s move to polarization maintaining optical couplers. They are the micro optic filter type devices which facilitate optical signal splitting while maintaining polarization with high extinction ratio. Being a coupler in the essence, they are capable of either splitting the light from an input polarization maintaining fiber between two output PM fibers or can join signals from two PM input fibers into a single PM output fiber.

By now, it is clear that what fiber optical couplers and PM optical couplers are. So, what exactly is a polarization maintaining tap coupler? It is a type of PM coupler which can split light waves with accurate tap ratio.

The polarization state can be aligned either with slow axis or fast axis of the polarization maintaining fibers. It is made from separate light crystals and the output port is also different from PM filter coupler. The benefit of using a PM tap coupler is that it can handle higher power and also has more precise coupling ratio than PM filter coupler. So, PM tap coupler is a better device with high optical performance and stability to be used for splitting high power linearly polarized light wave to provide multiple outputs while still preserving the polarization state.

This tap coupler can also be used as a power tap in a PM fiber system to monitor signal power without disturbing polarization state of the light traveling in PM fiber.

Applications of PM Tap Coupler

- Power sharing in polarization sensitive systems

- PM fiber interferometers

- Signal monitoring in PM fiber systems

- Coherent detection

- Fiber optic instruments

- Fiber sensors

Features of PM Tap Coupler

- Compact-in-line package

- Low insertion loss

- High extinction ratio

- Excellent reliability

- Superior stability

- Optimum optical performance

- Accurate tap ratio

- Can handle higher power

- Precise coupling ratio

If you have requirement of polarization maintaining tap couplers or another kind of PM coupler with custom specifications, contact one of the esteemed PM coupler manufacturers so that you can be sure of that you are investing your time and money at the right place.