Multiplexing is the method of maximizing the communication capabilities with the use of fiber optic cables. This methodology maximizes the communication capabilities and CWDM (Coarse Wavelength Division Multiplexing) combines multiple signals along the fiber optic cable on laser beams. Various wavelengths and channels are used for transmission and the functionalities are much higher than conventional standard Wavelength Division Multiplexing (WDM).

What are the specifications of a compact CWDM Mux and Demux?

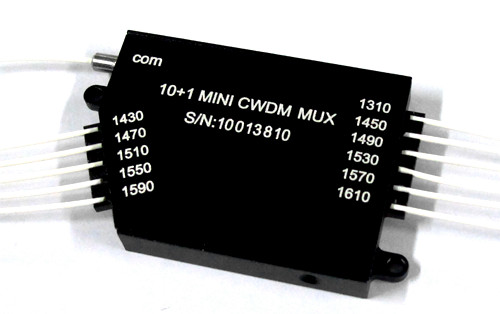

Low-cost, un-cooled lasers are used for CWDM and the system has channels at wavelength spaced 20 nanometers (nm) apart. The emission is occurring at 8 different channels namely – 1610 nm, 1590 nm, 1570 nm, 1550 nm, 1530 nm, 1490 nm, and 1470 nm. Also, up to 18 different channels are allowed with the wavelength ranging down to 1270 nm.

The energy emitted out of the lasers in a CWDM is spread out over a larger range of wave=lengths which is the energy from the lasers in a DWDM system. The tolerance is much higher up to ± 3 nm. A CWDM system is less expensive and consumes less power than a DWDM system.

Features of CWDM MUX or DEMUX

- It is compact and mini in size

- The device has low insertion loss

- It has wide pass band

- High channel isolation is possible with CWDM

- The state of CWDM MUX or DEMUX is highly stable and reliable

- It ensures Epoxy Free on optical path

Application that uses compact CWDM MUX or DEMUX

- Line Monitoring

- WDM Network

- Telecommunication

- Cellular Application

- Fiber Optical Amplifier

- Access Network

The optical signal is multiplexed from 4 or more devices into a single optical fiber. De-multiplexing is splitting a signal into separate signals for input into the electronic devices. It provides the ability to add or drop a single wavelength from a multiplexed signal which is providing access to common fiber segment between remote sites. The channel segmentation is very high in CWDM and the expanded seclusion prompts better outcomes. The CWDM channel arrangements have their utilization and applications additionally in the Cellular area. It devours Channel-8 CWDM at an incredible rate. The items should be utilized for straightforward transmission of signs and also use of filaments.