Ytterbium-doped mode-locked fiber laser Applications

Compared with traditional solid-state lasers, fiber lasers have the advantages of small size, low cost, good stability, high beam quality, and no need for water cooling. Compared with other fiber lasers, they are based on nonlinear polarization evolution. The NPE-based mode-locked fiber oscillator has the advantages of high pulse energy (on the order of nJ) and narrow pulse width (on the order of hundreds of fs, or even shorter). NPE mode-locking technology is a passive Kerr mode-locking technique that uses the nonlinear polarization rotation effect in the fiber to realize the Kerr effect, thereby realizing the output of the mode-locked laser. The erbium-doped gain fiber has the advantages of high doping concentration and high light-to-light conversion rate, and is suitable for preparing a high-power, high repetition rate mode-locked fiber laser.

The pulsed laser output pulse is a series of equally spaced pulse trains with extremely short pulse widths in the time domain, so it can achieve extremely high peak power with limited average power, which is widely used in biological imaging, medicine and industry. Processing and other fields. The mode-locking pulse is an equally spaced comb-tooth distribution in the frequency domain, which constitutes an optical frequency comb. The optical frequency comb is a bridge and hub for optical and microwave frequency sources. Its application and development pole this year. Great advancement in the fields of surveying, astronomy and other fields.

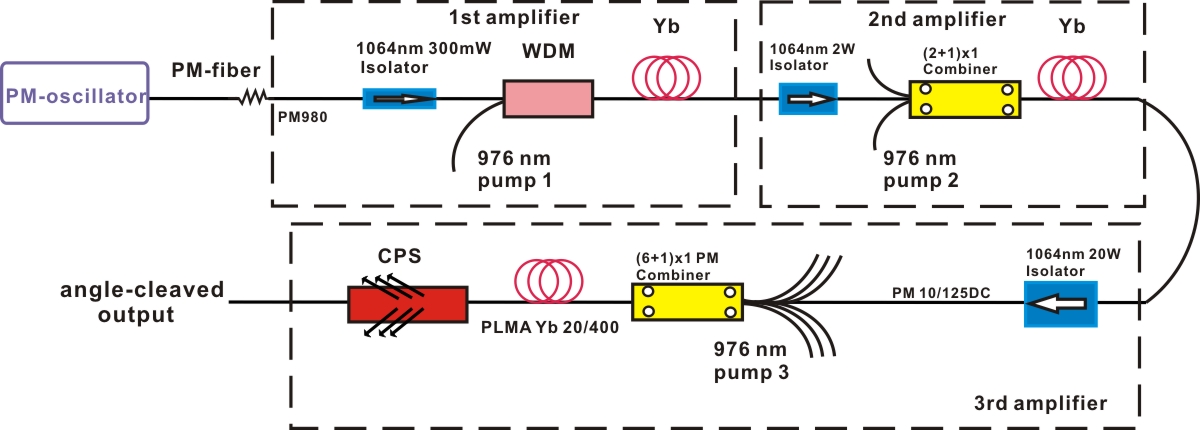

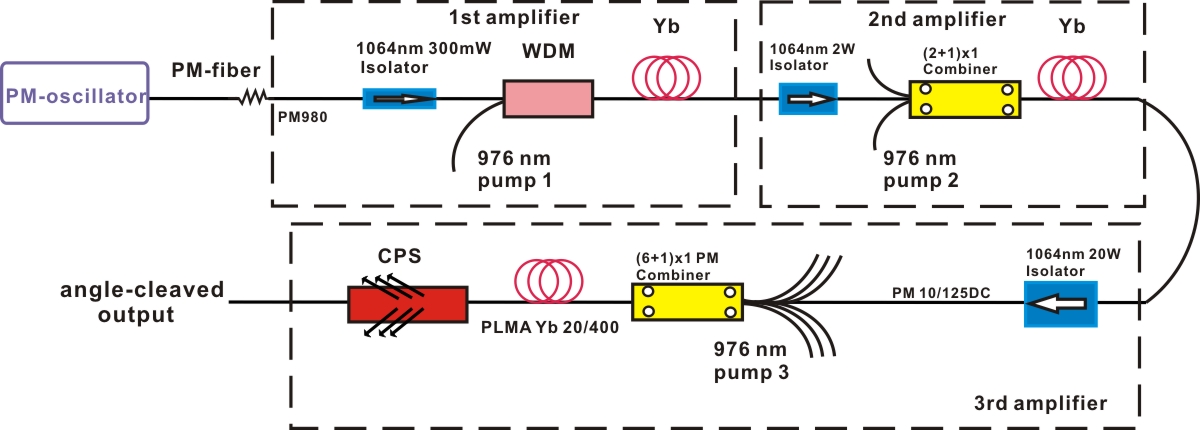

Schematic

According to the different dispersion in the annular cavity, NPE mode-locking can be divided into: soliton-type mode-locking, widening pulse-type mode-locking, and full-positive dispersion self-similar mode-locking. Different types of lasers have different characteristics, such as: soliton is easy to achieve stable mode-locking, but single pulse energy is low; widened pulse-like pulse-mode-locked spectrum is wide, can support a shorter compression pulse width, but it needs to be in-cavity The dispersion has a certain design; the full positive dispersion has a large pulse energy from the similar class, but the pulse is wider and the noise is larger.

The following is an example of a typical erbium-doped fiber-expanded pulse-type laser. The NPE erbium-doped mode-locked laser uses a half-wave plate and two quarter-wave plates to control and select the polarization in the cavity. The dispersion control in the cavity is realized by the transmission grating pair, thereby realizing the mode locking of the dispersion management class.

Fig.1: Structure diagram of erbium-doped fiber-mode-locked laser based on nonlinear polarization rotation

- 976nm pump: Provides energy as a pump source for the entire oscillator, typically a single-mode pigtailed 976nm semiconductor diode. It should be noted that in the actual construction, the pump module usually includes a pump laser protector to prevent the 1064 nm light reflected from the oscillator into the pump source to damage the pump source. In addition, when the oscillator energy is high or the mode-locked spectrum is wide, a 980nm optical isolator is needed to isolate the 980nm laser reflected in the cavity to prevent the pump source from being damaged.

- WDM: A wavelength division multiplexer that couples 1064 nm of signal light and 976 nm of pump light into the same fiber.

- Yb gain fiber: An erbium-doped gain fiber that absorbs 980 nm of pump light and amplifies the 1030 nm signal light.Fiber Isolator: isolate the 1064nm laser reflected in the cavity to prevent the pump source from being damaged.

- Fiber Combiner: The fusion of multiple fibers into a single fiber for pump coupling is the key to achieving full fiberization of high-power fiber lasers. Single-channel can withstand hundreds of W of power.

- CPS: Cladding Power Stripper, can effectively "strip off" residual pump and signal which transmit back in clad, meantime keep the amplified signal unaffected.

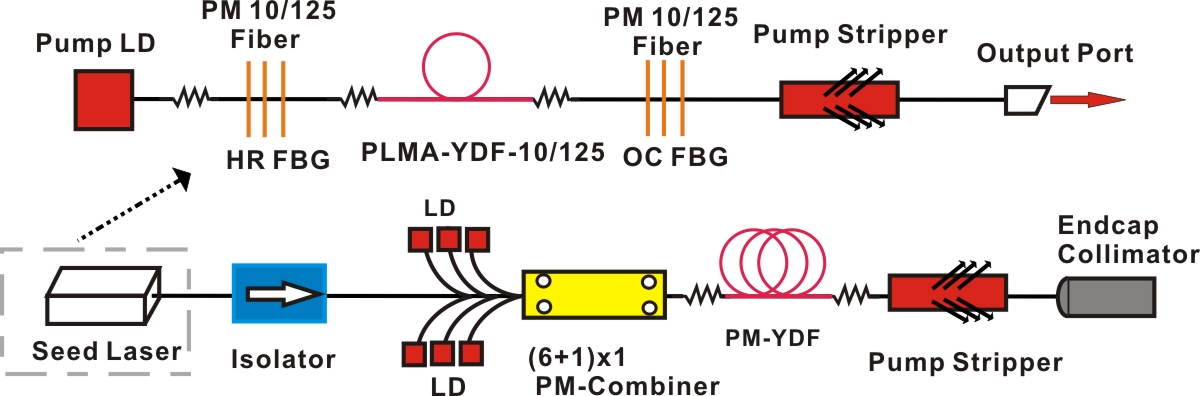

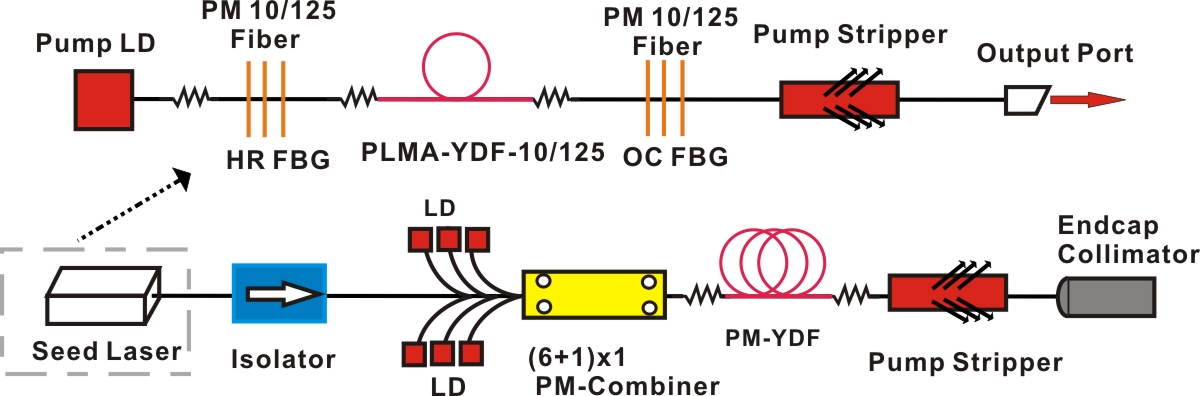

Fig. 2: Setup of the narrow-linewidth, linearly polarized seed laser and fiber amplifier

Introduction to construction and operation

Choose the right device. If a device is not suitable, it may cause low efficiency of the laser, poor pulse quality, and even a short life of the laser.

Choose a suitable working environment, including optical platform, ambient humidity, temperature, external vibration and noise, etc.

The above device is constructed and welded into a cavity according to the principle structure diagram, and the optical fiber is wound and fixed;

Turn on the pump source to a certain power level and adjust the coupling in the cavity (especially the coupling between the two collimators). If the cavity loss is too large, it is necessary to check whether there is damage to the device or solder joint damage.

After adjusting the pump source to the appropriate power, the output laser is observed using a spectrometer or oscilloscope (the latter requires the use of a photodetector to convert the optical signal into an electrical signal). Adjusting the waveplate state (two quarter-wave plates and one half-wave plate), when the stable bulge-like spectrum appears on the spectrometer and the equally stable pulses appear on the oscilloscope, the laser lock is achieved. mold. Lock the wave plate state.

Precautions

About loss: The source of loss in the cavity is mainly divided into space part and fiber part: space part includes stain on the surface of the device, grating diffraction loss and collimator coupling loss, etc.; the fiber part mainly comes from welding loss and some special fiber Transmission loss. Large loss will not only make the laser efficiency lower, but also cause the mold to be unable to be locked. In addition, it will sometimes cause Q-switching. The pulse peak power of the Q-switched pulse is extremely high and unstable, which may cause damage to the device.

About Dispersion: The difference in dispersion within a cavity can result in different types of mode locking. In the above cavity shape, the value of the dispersion in the cavity can be conveniently adjusted by adjusting the distance of the transmission grating. Generally speaking, when the net dispersion in the cavity is near zero, the mode-locked spectrum is the widest, so that the shortest pulse width can be supported, and the intracavity noise is the lowest at this time.

Pulse splitting: When the pump energy is too high, pulse splitting occurs, and pulse splitting causes the single pulse energy to become low and the pulse to be unstable.

Pulse compression: For most mode-locked lasers, the direct output pulse is a pulse with Chirped, so the pulse width is wide. In some applications, the pulse width is required. In this case, the dispersion compensation device is needed. The compression of the pulse results in a shorter pulse width.

DK Photonics offers a variety of passive components for building Ytterbium-doped mode-locked fiber laser systems, DK Photonics could provide pump combiner, optical circulator, optical isolator, tap coupler, collimator, WDM, in-line polarizer, and PBS with PM fiber or NO-PM fiber for 1.0um wavelengths. Contact DK Photonics regarding your requirements.

Click here to download the PDF file: