Fiber optic systems play a crucial role in modern telecommunications, offering high-speed data transmission and reliable connectivity. Within these systems, maintaining signal integrity and minimizing signal loss is paramount. Polarization-maintaining optical isolators (PMIs) are essential components that help achieve these objectives by managing the polarization state of light within the fiber optic system. In this blog, we’ll explore the importance of PMIs in fiber optic systems, their key features, and how they enhance performance.

Understanding Polarization Maintaining Optical Isolators

What are Polarization Maintaining Optical Isolators?

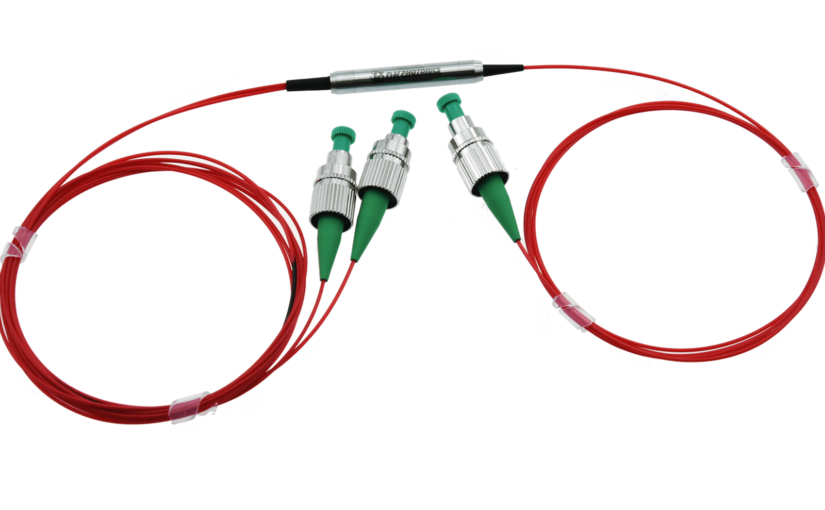

Polarization-maintaining optical isolators are devices designed to control the transmission of light within fiber optic systems while preserving the polarization state of the light. They are made up of specific optical components that selectively permit light to travel through one direction while obstructing light from returning in the other. In the fiber optic system, this unidirectional transmission ensures effective light propagation and prevents signal degradation.

Importance of Polarization Maintaining Optical Isolators in Fiber Optic Systems

1. Minimizing Signal Degradation

In fiber optic systems, signal degradation can occur due to back reflections, polarization fluctuations, and other sources of optical interference. PMIs play a crucial role in minimizing signal degradation by isolating the transmitted signal from reflected light and maintaining the polarization state of the transmitted light. This ensures consistent signal quality and reliability in data transmission.

2. Protecting Sensitive Components

Fiber optic systems often include sensitive components such as lasers, detectors, and modulators, which are susceptible to damage from back reflections and optical feedback. By incorporating PMIs into the system, these sensitive components are protected from harmful effects caused by unwanted reflections, ensuring their optimal performance and longevity.

3. Enhancing System Performance

PMIs enhance the overall performance of fiber optic systems by optimizing signal integrity, reducing signal noise, and improving system stability. By mitigating polarization-related issues and maintaining signal coherence, PMIs enable more efficient data transmission, higher data rates, and greater system reliability, ultimately leading to enhanced system performance and user experience.

Applications of Polarization Maintaining Optical Isolators

1. Telecommunications

In telecommunications networks, PMIs are used to manage signal polarization and prevent signal degradation caused by reflections and optical feedback. They are employed in optical amplifiers, wavelength division multiplexing (WDM) systems, and other critical components to ensure reliable data transmission over long distances.

2. Fiber Optic Sensing

PMIs are utilized in fiber optic sensing applications, such as distributed temperature sensing (DTS) and distributed acoustic sensing (DAS), to maintain signal integrity and accuracy. They enable precise measurement and detection of physical parameters, such as temperature, strain, and pressure, in various industrial and environmental monitoring applications.

3. Optical Instrumentation

PMIs find use in optical instrumentation and measurement systems, where accurate polarization control is essential for precise optical measurements and analysis. They are employed in spectroscopy, interferometry, and other optical characterization techniques to optimize signal quality and measurement accuracy.

Conclusion

Polarization-maintaining optical isolators are indispensable components in fiber optic systems, offering crucial benefits such as signal isolation, polarization control, and enhanced system performance. With their versatile applications and advanced features, PMIs play a vital role in enabling reliable and efficient data transmission across various industries and applications.