This is the world of optics and photonics. And in this, one very essential component is filter because it allows manipulation of light. A filter plays a very important role because it controls the spectrum of light, isolates specific wavelengths and eliminates unwanted noise.

Due to popularity of filters, different types have been introduced in the industry. But, recently, the fiber bandpass filter has gained popularity because it offers unique advantages. As it has become an attractive choice for many applications, people have almost forgotten the traditional filters.

In this post, we will discuss differences between fiber bandpass filter and traditional filters so that it’s easy for you to switch or select.

About traditional filters

Traditional filters are typically constructed from a thin layer of material with specific optical properties that allow it to transmit certain wavelengths of light while reflecting or absorbing others. Widely, they are used in photography, spectroscopy, and telecommunications.

The different shapes of traditional filters that you will find in the market are circle, square and rectangle. If you want to achieve optical functions, use the filters in conjunction with other optical components. Other components can be lenses and mirrors.

About fiber bandpass filters

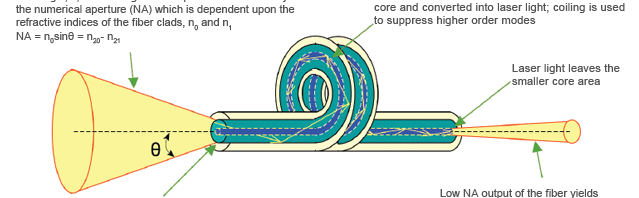

Fiber bandpass filters, on the other hand, are constructed from optical fibers that are specifically designed to transmit certain wavelengths of light while blocking others. A few applications of fiber bandpass filters are fiber-optic communications, optical sensing, and spectroscopy.

Because of the small size of the fiber bandpass filters, they are popular among optical engineers. The best part is that you can integrate these filters into existing fiber-optic systems.

Fiber bandpass filters vs. Traditional filters

The method of manufacture is one of the primary distinctions between fiber bandpass filters and traditional filters. The size and shape of the filters are also different. Fiber bandpass filters are typically small and can be integrated into existing fiber-optic systems, whereas traditional filters can be made in a variety of shapes and sizes.

Finally, the efficiency of the filters varies. Fiber bandpass filters outperform in terms of wavelength selectivity, signal-to-noise ratio, and long-term stability. They are also more resistant to environmental factors like temperature and vibration.

What should you choose?

The application dictates whether fiber bandpass filters or traditional filters are used. If you want a filter for a traditional optical system, choose a traditional filter. Here, the traditional optical system means a camera or spectrometer.

On the other hand, if you want a filter for fiber-optics system, choose a fiber bandpass filter. The fiber-optic system means an optical communication system or a fiber-optic sensor.

Another reason to choose a fiber bandpass filter is that it offers a lot of advantages over traditional filters. The advantages are higher selectivity, a higher signal-to-noise ratio and improved long-term stability. Also, they are more compact.

Based on the specific application, the choice between fiber bandpass filters and traditional filters depends. The choice is difficult, so we recommend consulting an optical engineer or filter manufacturer and determine the best option for your needs.