Fiber optic cables are used frequently for today’s telecommunication network because of their high bandwidth, high reliability and relatively low cost. For a layman, fiber optical cable or FOCs as they are often called, is a plastic or glass fiber which permits the transmission of communications over large distances and at higher rates. They present wire almost superfluous, because they pass the same, but there are a lot of loss. These cables are unique because they are not affected by electromagnetic interference. Use these cables in performing image used in the fiber.

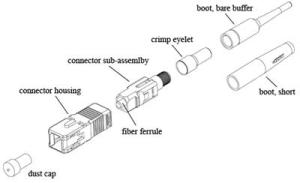

Each cable can not beyond the permissible limit. Fiber optic cable is very safe and more reliable than the traditional copper wire. Most of these cable to work in high-pressure environments. A fiber optic cable assembly includes a tube, a track and fasteners in addition to the conventional fiber bundles.

The cable tubes have both front and rear surfaces to it. These cables operate with the help of photons. These photos are transmitted to a second quantum dot which is placed between mirrors. These mirrors absorb the photons and bounce them back to the quantum dot until it absorbs it.

The fiber optic cables are used for carrying different services pertaining to data, voice, cable TV, and video. The fiber optic cables keeps the electronic equipments far away from environment that are subjected to high temperature, stem, dust, smoke and so on. The unique feature of these fiber optic cable is that stainless steel lens and fiber cables can be easily replaced without any further calibration.

For the installation of fiber optic cables, fiber optic cable blowers are designed. The unique feature of these fiber optic is that they carry information in the form of light. These cables are very useful in transporting both audio and video signals over short and long distances. If a fiber optic cable is broken, another cable has to be fitted in between the connectors rather than soldering or twisting them. Fiber optic technologies have found its place in many applications. They are widely used in telecommunications, CCTV security places, and local area networks and so on.

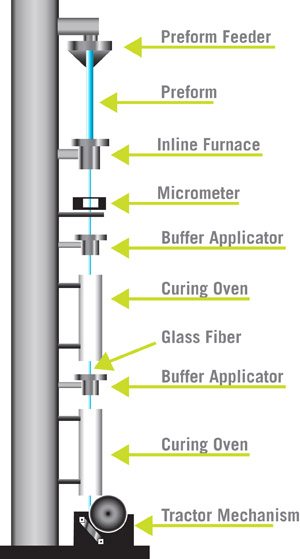

Glass fibers are made use of for fiber optic cabling. They hardly provide any change in the signals they carry over long distances. Engineers found that by adding some additional chemicals into the existing silica, they can change the properties of the glass used for the cable (glass fiber cable). Althouth, both glass and plastic can be used in the manufacture of cable, glass is the preferred one used in the manufacture of cable, used for long distance transmission communication. The purpose of glasses in total internal reflection transmission.

A fiber optic cable consists of a core which is made of glass silica. Through this core, the light is guided. The core is covered with a material whose refractive index is slightly lower than that of the core. Two optical fibers are connected via mechanical splicing or fusion splicing. This process involves lots of skills as microscopic precision is required to align them.

Regardless of the application used in optical fiber, they will stay here. Their unique features and capabilities, to ensure that they will continue to spread widely used in communications industry for many years.